| Forming a regional center for manufacturing spare parts and components |

|

6/11/2025 12:24:08 PM THACO INDUSTRIES is stepping up investment in the supporting industry sector, forming a regional spare parts manufacturing center.

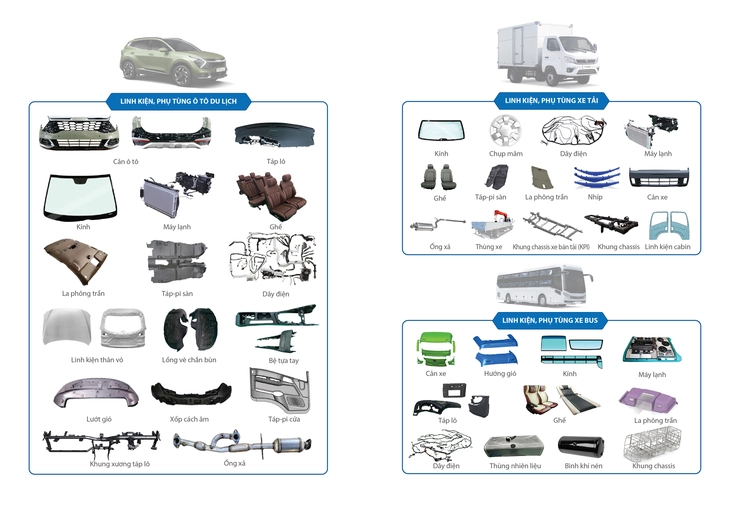

THACO INDUSTRIES’ new projects will be inaugurated and put into operation in early 2025. Photo: Thaco Expanding scale, upgrading technologyInvesting in the field of mechanical engineering and supporting industry very early to supplement THACO’s automobile assembly industry, after 22 years, together with the Mechanical Center, THACO INDUSTRIES has formed the LKPT Production Center in Chu Lai (Quang Nam) with a total investment of 550 million USD, including 12 factories with modern technology , meeting international standards . Combined stamping line at the Auto Body Frame Components Manufacturing Factory. Photo: Thaco THACO INDUSTRIES is currently a partner of major auto brands such as Kia, Mazda, BMW, Peugeot, Hyundai, Toyota, Isuzu... in supplying spare parts. Products include: body frame components (body components, trunk, dashboard frame, leaf springs, etc.), interior and exterior components (seats, bumpers, glass, ceiling panels, floor panels, interior and exterior plastic components, etc.), powertrain components (wheels, fuel tanks, exhaust pipes, etc.), electrical and refrigeration system components ( wiring assemblies, air conditioners, radiators, etc.). At the same time, we export to markets in North America, Australia, Germany, Korea, Japan, Poland and ASEAN countries. Wet technology ceiling panel production line at the Passenger Car Interior Manufacturing Factory. Photo: Thaco In order to contribute to the strategy of developing THACO branded vehicles and meeting market demand, the Group continuously upgrades technology, invests, and inaugurates a series of factories in early 2025, including: Auto Body Components Factory, High-end Auto Glass Factory, and Auto Electrical Equipment Factory. The factories have a total area of over 50,000m2, a total investment of 75 million USD, with advanced technology lines, large capacity, originating from the US, Germany, Italy, Japan... to improve LKPT production capacity, meeting export standards. Cutting - grinding - drilling machine at the High-end Auto Glass Factory. Photo: Thaco Back glass tempering furnace at the High-end Auto Glass Manufacturing Factory. Photo: Thaco Regional LKPT manufacturing centerThe Group actively researches and applies new technologies and materials to develop product portfolios according to customers’ specific requirements. At the same time, the Group focuses on developing the THACO Parts brand, meeting the standards of IATF 16949:2016, ISO 9001:2015, ISO 14001:2015... and the requirements and processes for manufacturing components according to global standards to serve the localization needs of automobile manufacturing and assembling enterprises. At the same time, the Group continues to diversify its supply sources of materials, improve product quality; increase the effectiveness of applying tools: ERP, MES, SCADA... in digitalizing management and production operations, meeting the requirements of sustainable development systems (ESG), greenhouse gas inventories... Robot paints plastic components at Plastic Components Factory. Photo: Thaco In the period of 2023-2027, the Group will continue to invest in the Tourist Car Interior Complex, cooperate, joint venture, and associate to invest in the technical rubber product manufacturing zone and the high-tech zone in Chu Lai; at the same time, there is a plan to invest in the Auto Interior and Exterior Components Factory in the North and the Mechanical and Supporting Industry Industrial Zone in the South. The Group has gradually established a regional LKPT production center with modern technology and large capacity (including the Passenger Car Interior Complex, Commercial Car Interior Complex and new generation factories), providing a variety of products, meeting the requirements of domestic automobile manufacturing and assembly enterprises and exporting to major markets. The Group also focuses on controlling costs so that products reach customers at competitive prices and provide convenient and efficient transportation and delivery solutions. Along with the efforts of enterprises, the preferential tax policy for the automobile industry until December 31, 2027 also contributes to motivating enterprises, including THACO INDUSTRIES, to continue expanding investment and increasing competitiveness . The implementation of the goal of forming a regional LKPT production center of THACO INDUSTRIES will contribute to increasing the competitiveness of domestic automobile manufacturing and assembly enterprises and deeply participating in the global LKPT supply chain . Some typical spare parts products of THACO INDUSTRIES. Photo: Thaco |

| tuoitre |